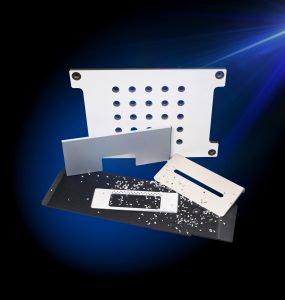

Aluminium, composite panels, plastic panels

Contract manufacturing: in our CNC machining centres, we use special vacuum clamping technology to produce high-precision functional parts or design elements for our customers from the business-to-business sector.

Large formats

With 6.4 m x 1.5 m machining area, even large panels are no obstacle

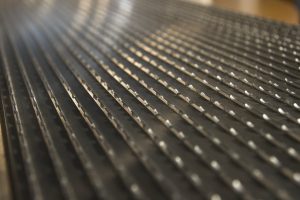

Surface-friendly

The vacuum clamping technology on our CNC milling centres contributes significantly to clean and damage-free processing.

Many materials

We process aluminium, plastic and composite panels, among others, on a CNC contract basis. Talk to us about your wishes.

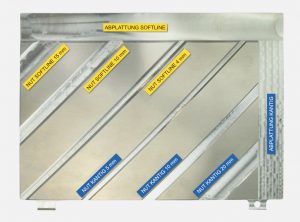

CNC surface machining

In CNC surface machining, we are the perfect partner for companies that require high-precision parts made of aluminium or composite panels.

Krotzer Fertigungstechnik has one of the most modern machine parks in flat profile and surface machining. Even large formats, with a machining surface of up to 6.4 metres in length and a width of 1.5 metres, are possible.

CNC production achieves a precision that would be unthinkable with manual machining. In our CNC full machining centres with special vacuum clamping technology, we are predestined to process orders in the shortest possible time and in high-tech quality. This also includes the damage-free production of corners and edge finishes using V-grooves on finished surface materials (aluminium, aluminium compound and aluminium compact panels).

We saw, mill and drill plastic and aluminium panels, HPL panels and sandwich panels, among others.

We accompany you during the development and manufacture prototypes

CNC-controlled machines are capable of producing a very wide range of different components. We will be happy to accompany you through the production of prototypes as early as the development stage and advise you on which material is best suited to your requirements profile.

Are you interested? Write to us: office@krotzer.at

Technical data CNC machines

- CNC surface machining four-axis up to 6400 mm length

- 1500 mm width and 200 mm height

- Aggregate equipment: 18 KW high-speed spindle incl. moving tool magazine as well as a grid boring mill and sawing aggregate

Materials

- Alu Compound

- HPL panels

- Plastic

- Aluminium panels from 0.5 – 6 mm thickness in standard and anodised quality

- Multilayer panels in wood or similar construction

Data transfer & editing

- Creation of accurate drawings based on your sketches

- DXF files

- DWG files

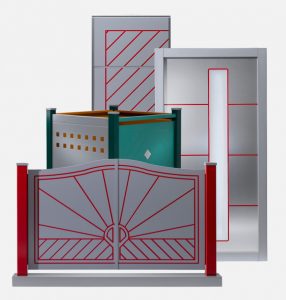

Egal ob Teile für Haustüren, Fenster, Aluminiumböden, Leichtbauteile oder Alufronten – den Möglichkeiten der CNC-Bearbeitung sind kaum Grenzen gesetzt. Wir denken in Lösungen und verfügen mehr als 30 Jahre Erfahrung. Darüber hinaus sind wir flexibel, schnell und vorausschauend.

High-precision parts according to your wishes

We produce in contract manufacturing according to your plans.

All parts are manufactured on site, at our premises. Your order is in the hands of our CNC experts at all times. On the one hand, this leads to fast processing of your orders and, on the other hand, to flexible processes. Short-term changes are no obstacle, as long as production has not yet started.

Special measuring instruments ensure a high fitting accuracy and compliance with all required dimensions.

Our quality is based on a high level of expertise, modern machinery, many years of experience and a high level of solution competence.

What we are strong in

- Production of CNC parts made of aluminium. Whether individual parts, small or large series.

- High-precision milling and drilling technology

- Feasibility studies to achieve the optimum combination of quality and economy in production

- Sample and prototype construction to achieve the best solution for your requirement profile

- Advice on the right choice of material – also with regard to surface finishing

- Finding solutions with special requirements for material, design and functionality

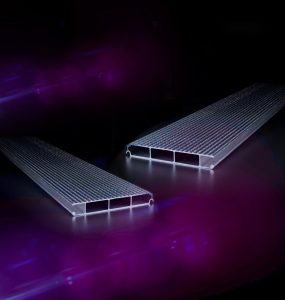

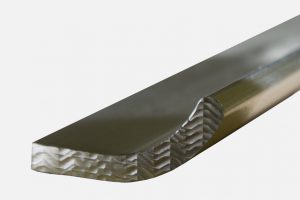

Sawing profiles with CNC support

In addition to CNC production, CNC sawing services are also part of our range of services. This ensures precise mitre cuts, among other tasks.

Technical data CNC saw

- 500 mm saw blade diameter with pneumatic clamping device

- Workpiece friendly feeding on roller feeder

- Sawing of profiles and aluminium flat material up to a diameter of 250 mm

Favourable further processing through our connected CNC grid boring mill.

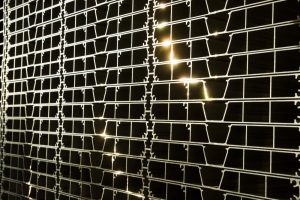

For years, we have been accompanying customers in the fields of garage doors, front doors, premium kitchens, fencing and balcony or niche products.

We would be happy to think about the implementation of your visions together with you. Write to us: office@krotzer.at